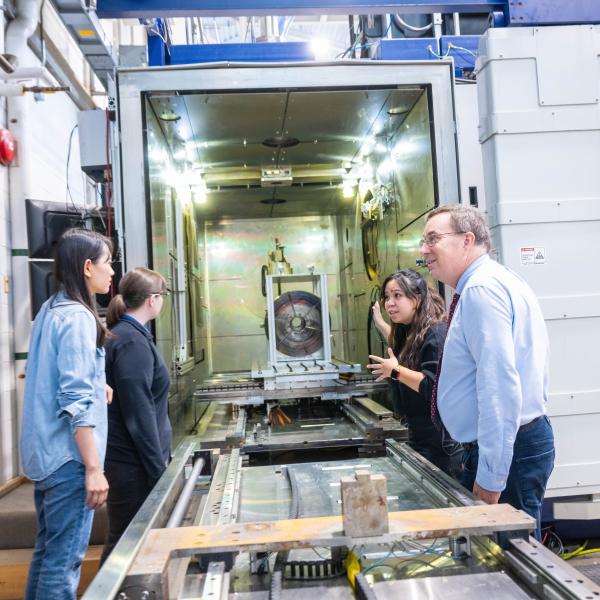

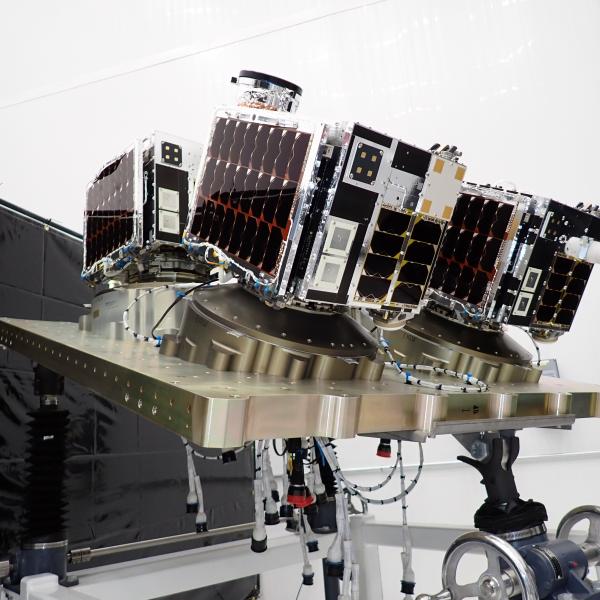

When security, military and commercial clients need powerful surveillance and reconnaissance tools, they turn to WESCAM. The 1,250-person subsidiary of global defence contractor L3Harris Technologies produces advanced electro-optical/infrared imaging systems that can identify objects over extremely long ranges, even in adverse weather conditions.

Meeting rigorous customer requirements isn’t simple. WESCAM’s high-tech cameras include more than a thousand components, from thermal imagers and infrared processors to vibration isolators and heat exchangers. And all those precision parts must fit inside a compact sphere that can be mounted on aircraft, boats or land-based vehicles and be reliable enough to withstand demanding missions from intelligence to search and rescue.

That’s why the Hamilton, Ont. company works with the Additive Manufacturing Innovation Centre (AMIC) at nearby Mohawk College.

“Additive manufacturing is part of the puzzle of making all this stuff fit,” says WESCAM engineer Nick Moore. “You can produce parts that you can’t make in any other way.”

On the forefront of additive manufacturing

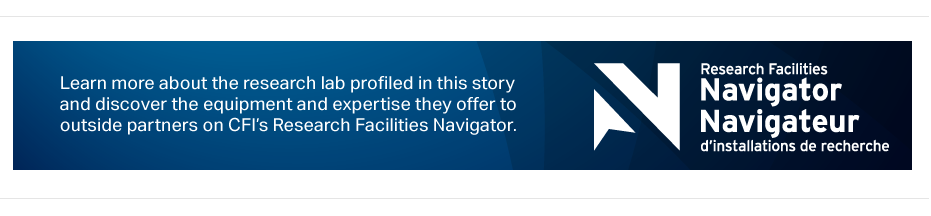

Funding from the CFI in 2013 allowed Mohawk College to become the first educational institution in Ontario to acquire a metal 3D printer. Subsequent CFI funding and other investments have kept them at the leading edge.

Today, AMIC works with a range of industry partners to solve their manufacturing challenges, optimize processes and develop new products using a suite of equipment for the three main types of 3D printing: fused deposition modelling, binder jetting and selective laser sintering.

Since 2014, they’ve undertaken more than 350 applied research projects. Those include dual-use and defence projects for partners like WESCAM, Burloak Technologies, MDA and General Dynamics.

It also includes working with manufacturing, aerospace, healthcare and materials companies and academic institutions, creating everything from toilet bowl scrubbers to tools for inspecting nuclear fuel rods.

“We have a talented team here that are able to figure out solutions to any problem,” says Simon Coulson, AMIC’s general manager.

In addition, AMIC can provide training sessions on the latest additive manufacturing technologies and recommend the best tools to meet a company’s specific needs.

“[It’s] a one-stop shop for everybody to come in and learn about additive manufacturing, how it can benefit you,” he says.

Prototyping and beyond

Many companies recognize the value of additive manufacturing for prototyping new parts or devices. For WESCAM, working with AMIC lets them experiment with different ideas and designs for new custom parts.

But the applications don’t stop there. For certain business cases, additive manufacturing can replace traditional methods, says Coulson, pointing to the example of a fuel injector nozzle for airplane engines.

“By switching from traditional manufacturing to additive, we’ve made the part four to five times more robust,” he explains. “Over the life of the aircraft, it’s going to save significant cost.”

Additive manufacturing can also help newer ventures cross the “valley of death” in the R&D journey — the stage when orders start coming in but sales volumes aren’t high enough to justify the upfront cost of traditional manufacturing equipment.

According to Moore, AMIC is giving Ontario manufacturing an edge at a critical time for the sector. “It’s making sure that we’re using and maximizing the use of new technology at all times to stay ahead,” he says. “[And] it’s keeping that technology and that know-how in Canada.”

The research project featured in this story also benefits from funding from Natural Sciences and Engineering Research Council of Canada.