Around the world, additive manufacturing is producing everything from engine parts to custom dentures one tiny layer at a time.

Introduced a decade or so ago, these transformative techniques can make complex three-dimensional structures that aren’t otherwise possible. They’re far less wasteful than traditional “subtractive” machining, which generates a scrap heap of discarded shavings. They’re faster than casting. And they’re much cheaper if all you need is a few units, rather than thousands.

With CFI funding, the University of British Columbia (UBC) has established the most extensive additive manufacturing research capabilities in Western Canada. And that suite of high-tech tools is advancing research in a host of disciplines.

UBC’s high-tech toolbox

Clean energy researchers are using a multi-target sputtering system, which can combine different metals to create better batteries and the electrolysers required to convert water to clean-burning hydrogen.

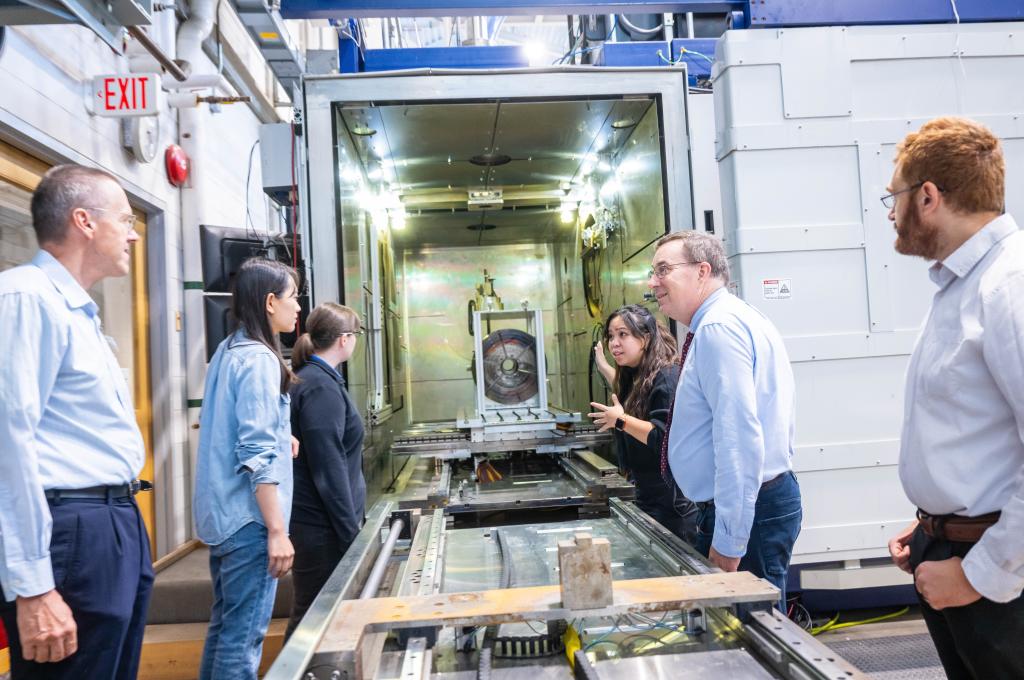

Researchers developing the next generation of jet engine components are leveraging a high-power laser system to print new parts before finishing them with a conventional machining tool to achieve the precision required by the aerospace industry.

CFI funding also allowed UBC to team up with Canmora Tech Inc., a local company that produces additive manufacturing tools. Together, they transformed an existing welding machine at UBC into a one-of-a-kind additive manufacturing platform that uses an electron beam instead of a laser to melt layers of metallic powder.

But Canmora’s big innovation was incorporating a vacuum furnace that provides a much more consistent operating temperature than other electron-beam additive manufacturing machines, creating higher-quality products for the auto industry and other sectors. “There’s no other machine like it,” says Canmora CEO Ralf Edinger.

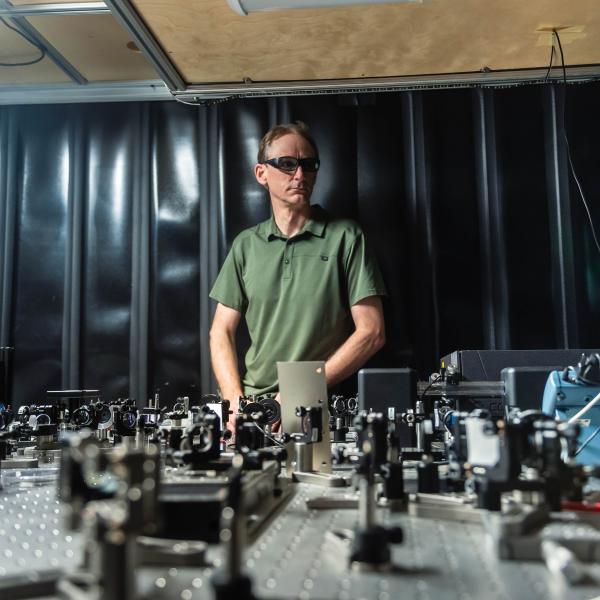

And thanks to a specialized electron microscope, UBC materials engineering researchers can scrutinize the microstructural integrity of those parts for strength and fracture resistance. “It’s one of the most capable in the world for characterizing materials in three dimensions,” says Warren Poole, Canada Research Chair in Through Process Modelling of Advanced Structural Materials.

In turn, those insights can help the automotive sector shift to lighter metal alloys that reduce weight of a vehicle — and therefore its fuel consumption — without sacrificing strength.

Training students, generating spin-offs

UBC’s cutting-edge infrastructure benefits students in an advanced manufacturing undergraduate program launched in parallel with the new research facilities. “Being able to work with really state-of-the-art equipment adds tremendously to their educational experience,” says Poole.

The infrastructure has also helped attract new faculty members and generated spin-off ventures. It’s supporting R&D partnerships with industry, including aerospace manufacturer Pratt & Whitney Canada and Rio Tinto Aluminium, which has extensive Canadian operations.

And it has fuelled the growth of Canmora, which leveraged the experience of creating UBC’s electron-beam machine to sell additive manufacturing platforms to advanced manufacturing companies around the world. “Without the help of the CFI and UBC in this, we wouldn’t be here in this position right now,” says Edinger.

With the global additive manufacturing sector growing by tens of billions of dollars a year, he believes these kinds of investments are crucial. “Unless we work on this, we will not be competitive with other countries,” he says.

The research project featured in this story also benefits from funding from the Canada Research Chairs Program and the Natural Sciences and Engineering Research Council of Canada.