Canada is a major player in the trillion-dollar global mining industry, producing critical minerals like copper, nickel, cobalt, lithium and rare earth elements.

But extracting those minerals — which are key to everything from solar panels to smartphones — is an expensive undertaking that comes with big environmental costs. Simply crushing and grinding rock consumes three percent of the world’s electricity. Waste rock can contain toxic elements, and processing minerals uses significant amounts of energy and water.

The better that mining companies understand the composition of the rock they’re dealing with at every stage of the mining process, the more they can reduce those costs and improve productivity.

Today, high-tech sensor technologies offer detailed analysis of the concentration of critical minerals in materials as they are being mined and processed. But each one has its limitations.

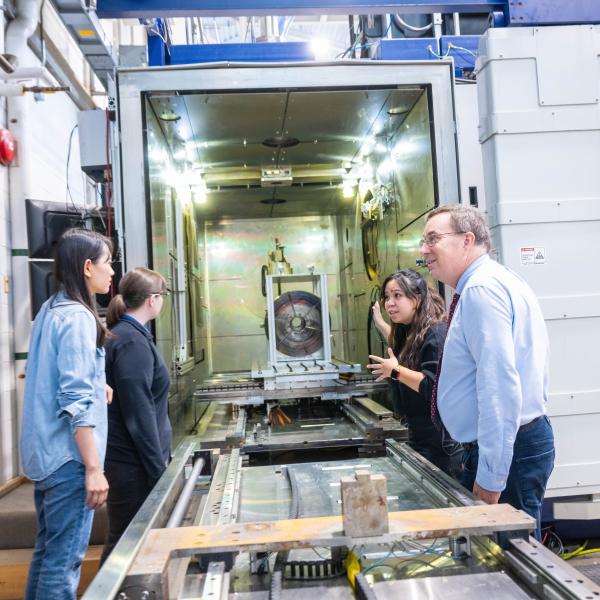

“We’re always looking at new sensors that can do more,” says Bern Klein, professor of mining engineering at the University of British Columbia (UBC) and co-founder of MineSense, a Vancouver company that sells sensing systems to mining operations around the world.

Higher resolution, better insights

The sector already uses laser-induced breakdown spectroscopy (LIBS), which vaporizes rock samples with high-energy lasers, creating a light-emitting plasma. Because different elements emit their own unique pattern of peaks in the light spectrum, analyzing those peaks reveals the concentration of elements in the sample.

However, when the peaks of different elements are too close together, it’s difficult to distinguish one “fingerprint” from another. So Klein teamed up with UBC physicist David Jones to apply laser ablation dual-comb spectroscopy (LA-DCS).

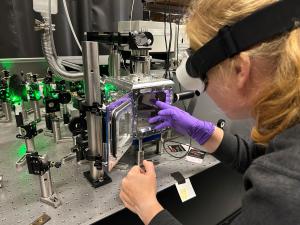

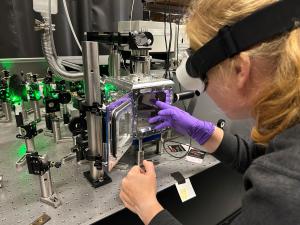

Just as each element has a unique light-emission fingerprint, it also has a unique light-absorption fingerprint, Jones explains. The recently developed LA-DCS process measures that absorption, generating much higher-resolution results than LIBS.

“We can really determine what element is there because we can zoom in and look at very, very narrow wavelengths,” he says.

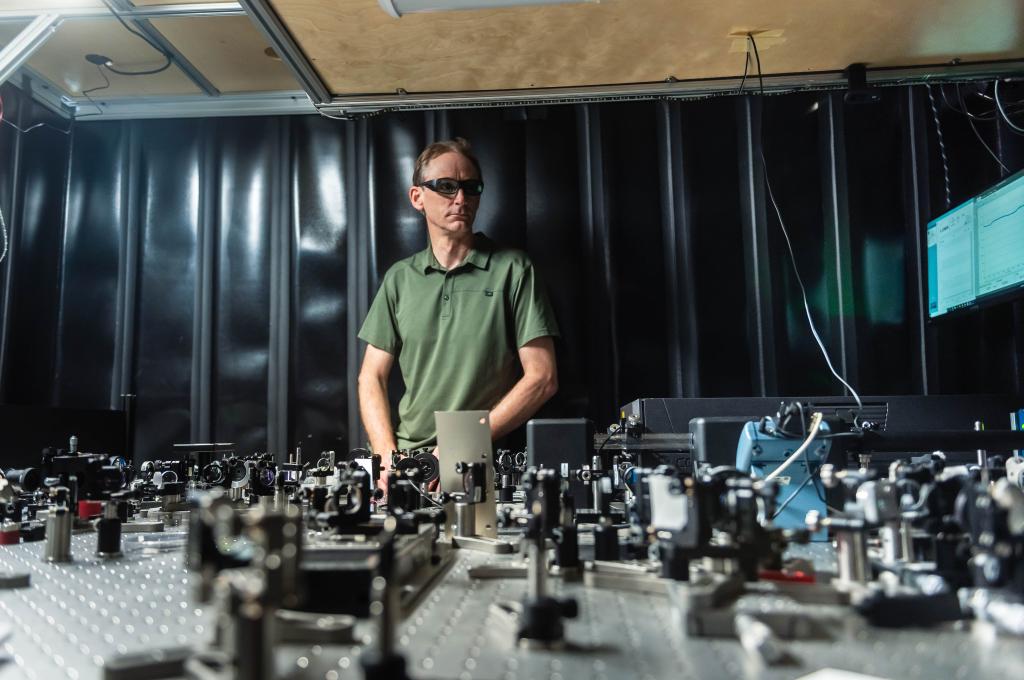

With CFI support, the researchers were able to purchase commercial lasers for their research — housed in UBC’s Blusson Quantum Matter Institute where Jones is a Principal Investigator — rather than build their own. “That let us hit the ground running, so to speak, and more rapidly get to a point where we can start to demonstrate it and see if we can move this to the mining industry,” Jones says.

Smarter mining, better bottom line

Klein envisions using LA-DCS to analyze core samples during the mineral exploration stage in far more detail than is currently possible, so companies can identify the most profitable places to mine.

And while LA-DCS sensors aren’t currently robust enough to mount on the bucket of an excavator or on conveyor belts, they could be used to calibrate the sensors, such as X-ray fluorescence sensors, that are already used in those settings.

By providing operators with more precise real-time readings right at the mining face, they could ensure less waste ends up at the mineral processing plant and fewer valuable minerals are discarded as waste.

According to Maarten Haest, VP of Geoscience at MineSense, investments in this kind of R&D make the country’s mining industry more profitable and more sustainable.

“Products from successful mining research in Canada are most likely to generate benefits for Canadian mines first, ensuring they stay at the forefront of technology innovation,” he says.

The research project featured in this story also benefits from funding from the Natural Sciences and Engineering Research Council of Canada.