When a family-owned Ontario playground equipment company decided to expand its market into adult and outdoor fitness equipment, it turned to the labs at Lambton College’s Centre for Industrial Material Development for help. Active Playground Equipment Inc., in the village of Point Edward in southwestern Ontario, has been designing and manufacturing jungle gyms and other outdoor play spaces for schools, parks, daycares and homes since the early 1990s. The company’s owners, brothers Ben and Andrew Prins, recently decided to up their game by adding adjustable resistance, a galvanized finish, molded rubber grips and electronic device holders to make it easier for grownups to incorporate the equipment into fitness programs. To protect the added features of this “third generation” of playground equipment from harsh winters, the company needed to develop a new coating for the metal, wood and other materials.

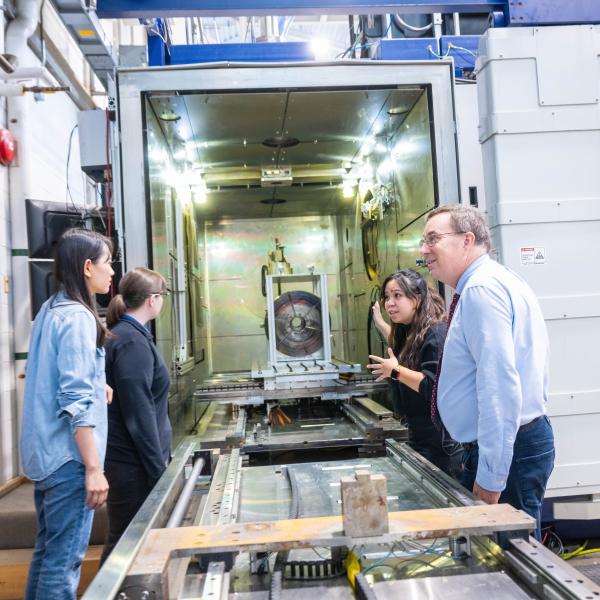

That’s where Shahram Karimi and his team of research students come in. Since it can take months or years for materials to start to corrode under normal outdoor conditions, the company needed a way to accelerate the process to test their protective coatings in order to determine the optimal composition and how thickly it needs to be applied to work. Using corrosion chambers, high temperature and pressure autoclaves and lab equipment that generates a high voltage, researchers subject different combinations of coatings applied to wood and metals to aggressive, highly corrosive and detrimental environments to speed up their deterioration and corrosion rates.

The team then uses a high-powered lab equipment — including scanning electrochemical and electron microscopes, an atomic force microscope and a micro-hardness tester, among other things — to examine how well the materials hold up. This information will allow the company to make informed decisions on the design for their new playground equipment, better positioning them to tap into the new markets they seek.

“Collaborating with small businesses like this one is invaluable to how colleges can contribute to developing new technologies,” says Karimi. “The company benefits from finding answers to their challenges, and we benefit from the chance to demonstrate the value of our knowledge, and to learn from the work.”