Related Stories

Quebec

A robo-lutionary way to build homes faster

How smart, mobile robots could solve the labour shortage that’s crippling Canada’s construction industry

Ontario

Trailblazing company turns chaff to caff

With help from a University of Guelph lab, a small business in southern Ontario is finding opportunity in agricultural waste

Ontario,Quebec,Alberta

PART I: Innovation starts with an idea

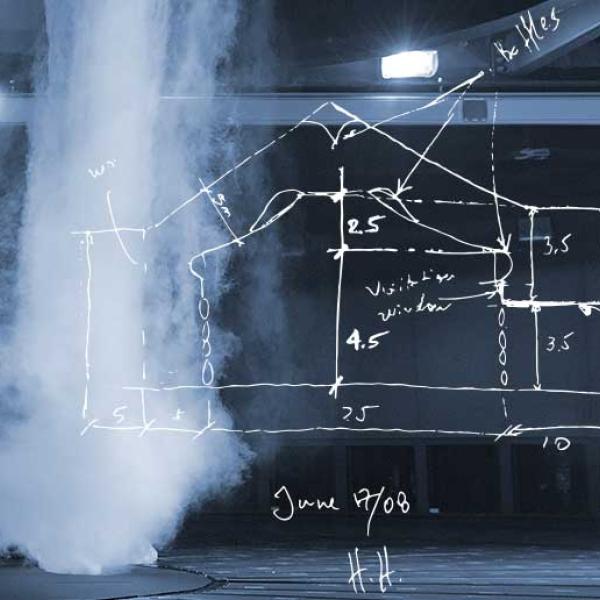

Reinventing wind science, from sketch to engineering revolution. Western University.